Die cutting Services

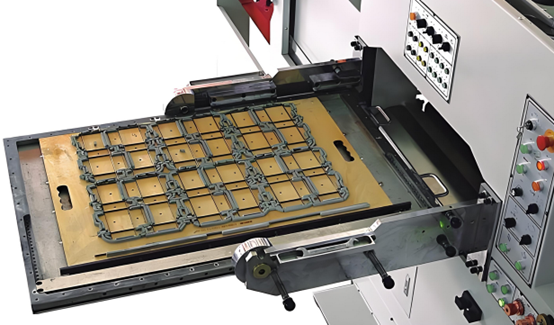

Die-cutting/Punching

Product description:

Punching is a kind of cutting process in the post-processing of raw materials, the sheet material is cut according to the design drawings, under the action of pressure, rolled and cut into the required shape, or cut into the shape of the forming process, the shape is no longer limited to straight edges and right angles, but any shape. Or the use of crimping knife or crimping die, through the action of pressure on the material to press out the line marks, or the use of rolling wheel in the sheet rolled out the line marks, so that the sheet can be bent according to the predetermined position of the shape. Usually, punching is the combination of punching knife and crimping knife in the same template.

Die-cutting process flow is: row knife - on the plate - set the pressure of the machine - adjust the rules - paste sponge adhesive - test pressure die-cutting - adjust the pressure - formal die-cutting - clear waste.

Steel knife die-cutting is the most common form of custom die-cutting, the method is according to customer specifications for the imitation of "steel knife", to stamping way to cut out parts. Rotary die cutting is mainly used for bulk web cutting. Rotary die cutting is used for soft to semi-hard materials, where the material is pressed into a cylindrical die and cut between the blades on a cylindrical anvil. Laser die cutting is used for cutting materials where flat blade die cutting does not achieve the desired results and where accuracy and speed are required, laser cutting uses a non-thermal laser beam to shape the customer specified material to achieve custom shapes and sizes.

Service Type:

1, Fast order processing

2, Tolerance control within +/-0.005mm

3, High volume production

4, Sample and small batch production

5, Design and technical support

6, CAD/CAM (Computer Aided Design/Manufacturing) support

7, Customised moulds and tooling

8, Material selection and sourcing

Applications:

Electro-acoustic, healthcare, display signs, safety and protection, transportation, office supplies, electronics and power, communication, industrial manufacturing, home leisure and other industries. Used in mobile phones, MID, digital cameras, automotive, LCD, LED, FPC, FFC, RFID and other products, gradually used in the above products bonding, dust, shock, insulation, shielding, thermal conductivity process protection. Used to process the die cutting materials are rubber, single-sided, double-sided tape, foam, plastic, vinyl, silicone, metal thin tape, metal sheet, optical film, protective film, screen, hot melt adhesive tape, silicone adhesive and so on.

Product type:

Three-dimensional type products: such as insulating paper, insulating film after punching and creasing process to form a variety of shapes, such as cylindrical, rectangular, square, prismatic conical, polygonal and so on;

Folding type products: insulating paper, insulating film after punching and creasing process, after manual or thermoforming process;

Plane-type products: a variety of different types, different specifications, the structure of the complexity of different, different shapes of gaskets and so on;

Protective film: mainly used to stick on the surface of other products to play a protective role;

Rubber + non-woven fabric: mainly dustproof, waterproof role;

Other categories: such as conductive cloth, copper foil, aluminium foil, etc., mainly for shielding, conductive role;